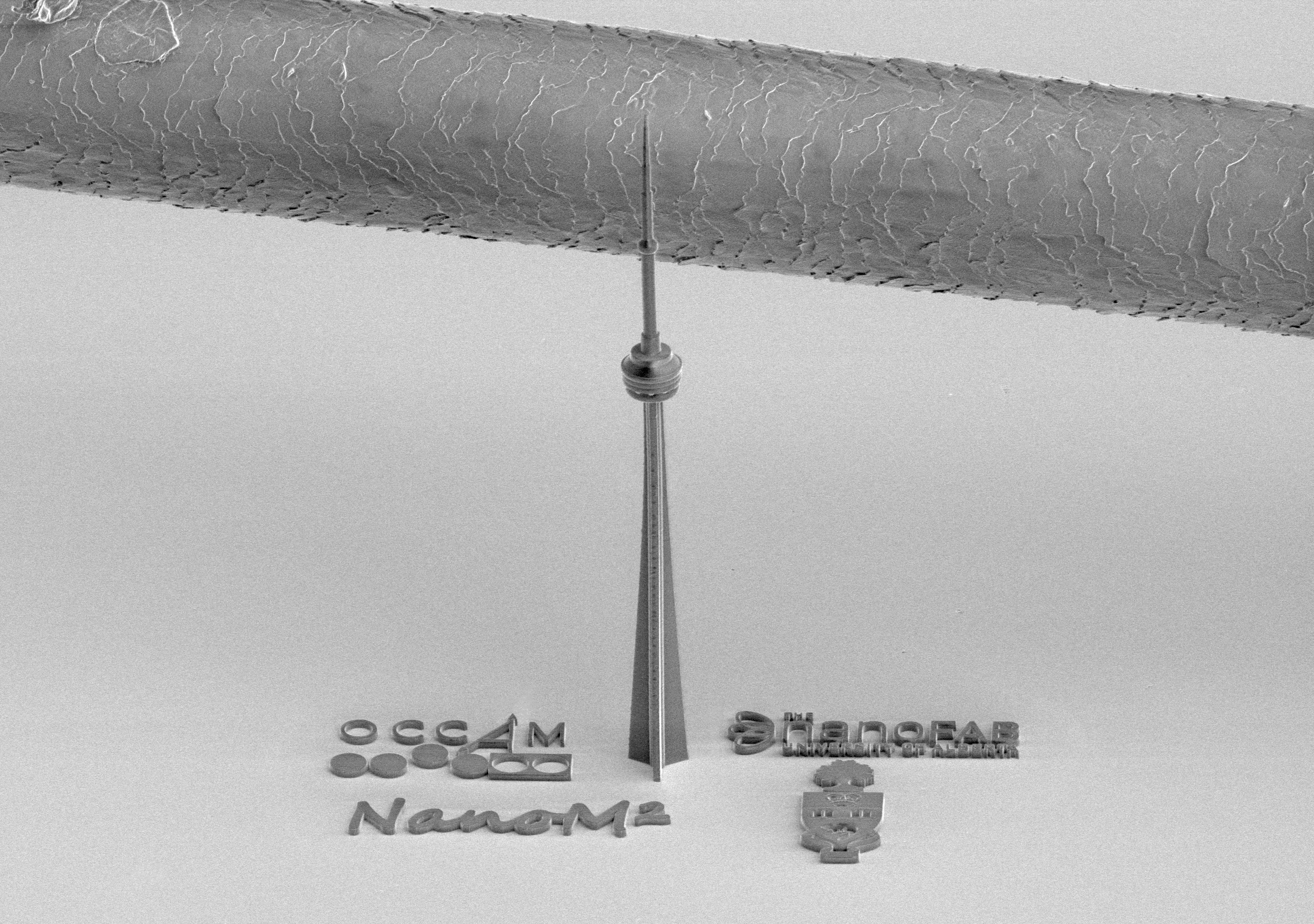

Image Description: Scaled down by a factor of 2,500,000x and invisible to the naked eye, the CNano Tower stands only twice as tall as the human hair behind it. To produce this tiny Canadian icon, with details on the observation deck in the nano-meter range, a new form of nano-3D printing called two-photon polymerization scans a laser back and forth, layer by layer, which cures a specialized plastic gel into the final shape. While limited manufacturing techniques on the micrometer and nanometer scales have long been the barricade to unlocking new industries like nano-robotics, non-invasive surgery, nano-machinery, or drug delivery, nano-3D printing offers new design versatility that is revolutionizing the nanoscale landscape, and skyline.

Why did you conduct this research? Producing complex shapes on the nanoscale and microscale has been a major roadblock towards designing small scale devices such as nano-robotics, non-invasive surgery, nano-machinery, or drug delivery. Nano-3D printing offers unparalleled resolution in this space and holds the potential to revolutionize small scale designs.

Technique: The CNano tower was designed in Solidworks software and produced using Two-Photon Polymerization, a 3D printing technique with resolution almost 1000x smaller than a human hair. The image was taken using a high-resolution Scanning Electron Microscope at the Ontario Centre for the Characterization of Advanced Materials (OCCAM).

Acknowledgments: Professor Tobin Filleter of MIE, Sal Boccia and Peter Brodersen of the Ontario Centre for the Characterization of Advanced Materials (OCCAM), NanoFAB at the University of Alberta.